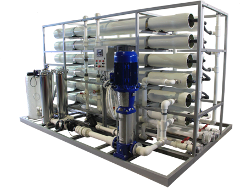

UF systems

Ultrafiltration (UF) is a membrane filtration process similar to Reverse Osmosis, using hydrostatic pressure to force water through a semi-permeable membrane. A membrane or, more properly, a semi permeable membrane, is a thin layer of material capable of separating substances when a driving force is applied across the membrane. Once considered a viable technology only for desalination, membrane processes are increasingly employed for removal of bacteria and other microorganisms, particulate material, and natural organic material, which can impart color, tastes, and odors to the water and react with disinfectants to form disinfection byproducts (DBP). As advancements are made in membrane production and module design, capital and operating costs continue to decline.

|

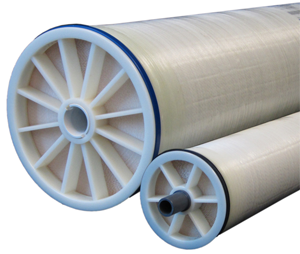

Ultrafiltration uses hollow fibers of membrane material and the feed water flows either inside the shell, or in the lumen of the fibers. Suspended solids and solutes of high molecular weight are retained, while water and low molecular weight solutes pass through the membrane. Ultrafiltration is not fundamentally different from reverse osmosis, microfiltration or nanofiltration, except in terms of the size of the molecules it retains Ultrafiltration (UF) is a pressure-driven barrier to suspended solids, bacteria, viruses, endotoxins and other pathogens to produce water with very high purity and low silt density. The primary removal mechanism is size exclusion, though surface chemistry of the particles or the membrane may affect the purification efficiency. UF can be used as pretreatment for reverse osmosis systems or as a final filtration stage for deionized water.

Advantages of Ultrafiltration:

- Low fouling membrane modules

- Excellent filtration performance with high flux

- High chemical resistance and temperature tolerance for effective membrane cleaning

- Very fine nominal pore diameter

- High removal efficiency of bacteria and viruses

- Dead-end or concentrate bleed flow capabilities

- Can be periodically back washed and air scoured to improve performance and extend operating life by removing the fouling layer

- Simple, vertical, modular design allows low cost, compact systems

| Model | Filtering surface, m2 | Flow rate, m3/h | Dimensions LхWхH, mm |

| UF 0.4 | 220 | 8 - 16 | 600х1400х2000 |

| UF 0.6 | 330 | 15 - 24 | 900х1400х2000 |

| UF 0.8 | 440 | 20 - 32 | 1200х1400х2000 |

| UF 10 | 550 | 25 - 40 | 1500х1400х2000 |

| UF 04/4 | 220 | 8 - 16 | 600х2000х2000 |

| UF 10/4 | 550 | 25 - 40 | 1150х2000х2000 |

| UF 20/4 | 1100 | 50 - 80 | 4000х1600х2950 |

| UF 30/4 | 1650 | 75 - 120 | 3300х2230х2950 |

| UF 40/4 | 2200 | 80 - 180 | 4200х2230х2950 |

| UF 50/4 | 2750 | 90 - 220 | 5000х2230х2950 |

| UF 60/4 | 3300 | 120 - 300 | 5900х2230х2950 |

| UF 2x60/4 | 6600 | 240 - 600 | 13800х3000х3180 |