F-700 Sand Separators (Hydrocyclones)

Applications: sand separator for well applications

Applications: sand separator for well applications

Standard Characteristics:

- Filter housing material of construction: Carbon Steel ST37.2

- Pre-treatment: sand blasting up to Sa 2.5 grade

- Exterior & Interior coating: electrostatic oven baked polyester-epoxy powdercoating with a thickness of 150-200 micron

- Connections: VIC, Male Threaded and Flange

- Maximum recommended working pressure: 10 bars (145 psi).

- Inlet is tangential to the body

- Equipped with anti- vacuum valve

- Conical rubber protection or expendable connection on the joint betweenhydrocyclone and the sedimentation tank

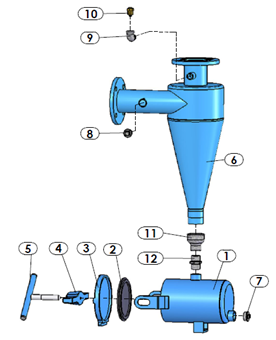

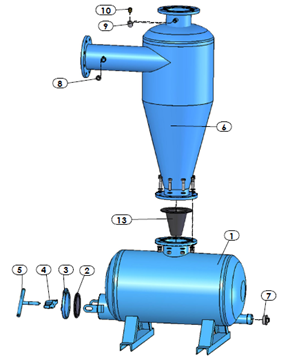

Operation:

Water enters the hydrocyclone via the tangential inlet which creates a spiral flow along the walls of the filter. The centrifugal force separates the waste and sand particles and pushes them towards the walls of the sand separator. Those particles gravitate downwards and into the sedimentation tank, while clean water moves upwards and exits through the top outlet.

For the sand separator to operate correctly, the lead loss must remain between 2-5m. The separation efficiency is not affected by the accumulation of dirt in the sedimentation tank. The sedimentation tank is drained by opening a flush valve for a few seconds manually or automatically by timer.

|

1. Sedimentation tank 2. Neoprene cover 3. Cover 4. Tightening bracket 5. Handle 6. Body 7. Male plug 8. Male plug 9. Elbow 10. Anti-vaccum valve 11. Steel insert 12. Steel insert 13. Rubber insert |  |

|